Quantify Your Industry 4.0 Investment

We help manufacturing and engineering leaders implement strategic Industry 4.0 solutions like digital twin and Industrial IoT, delivering quantifiable ROI and operational excellence.

They bring binders. We deliver breakthroughs.

Unlock Real ROI from Industry 4.0

Industry 4.0 isn't just theory; it's a practical strategy for today's plant floor.

We help you achieve measurable results: increased efficiency, reduced costs, and enhanced agility.

Solutions like digital twin for predictive maintenance, 3D laser scanning for precise facility upgrades, and data acquisition systems for real-time visibility all translate directly into significant financial returns.

Learn more about a practical, actionable Industry 4.0 strategy in one of our most popular blog articles: Tangible ROI with Practical Industry 4.0 Applications

Navigate Smart Manufacturing with Confidence

Adopting Industry 4.0 has complexities: integration, cybersecurity, and skill gaps.

We don't downplay these challenges; we solve them.

Whether it's brownfield or greenfield, we develop phased roadmaps and manage the cultural shifts needed for success.

Leveraging manufacturing execution systems (MES) as your smart factory's central nervous system and integrating IIoT into existing infrastructure ensures seamless digital transformation.

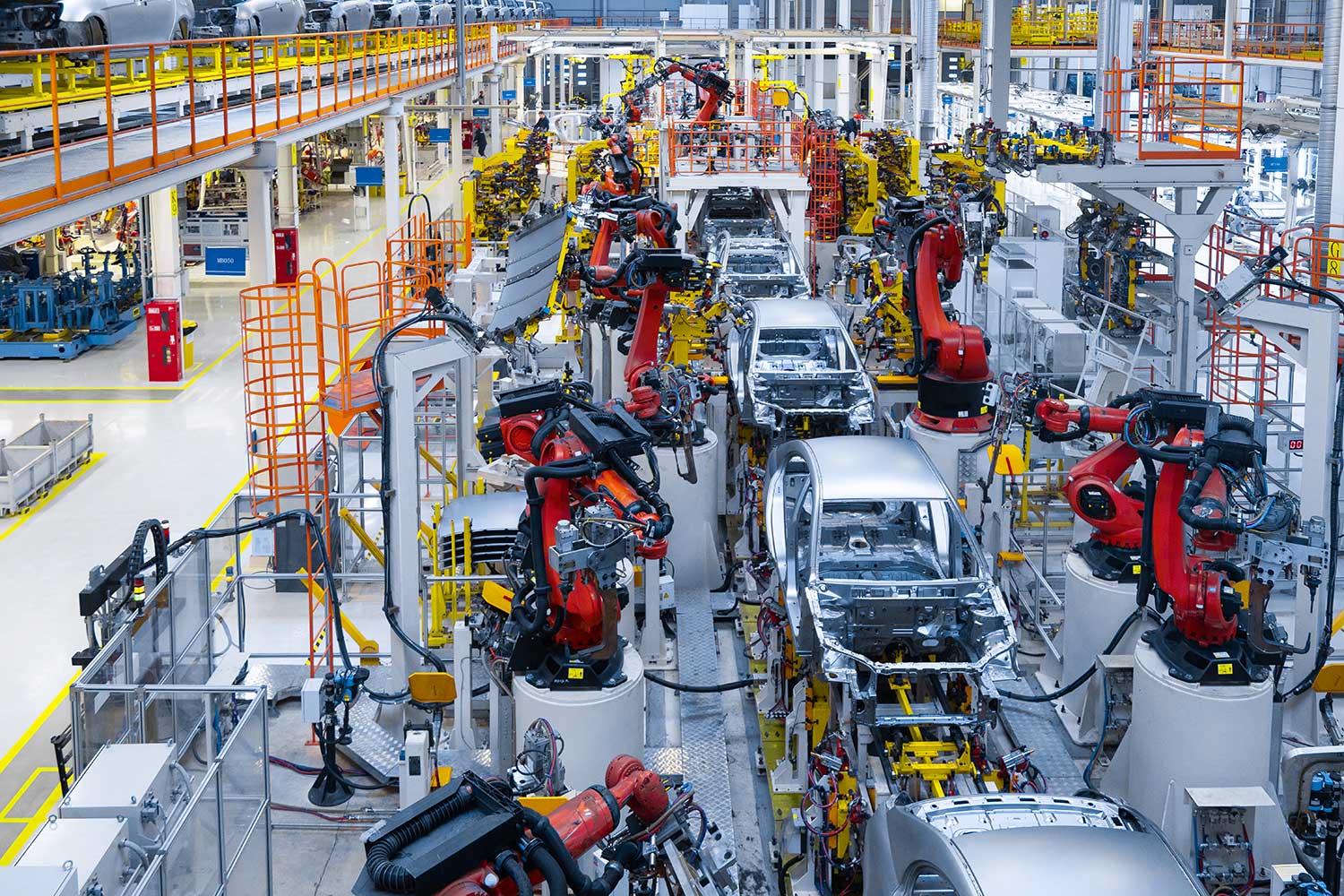

See What an Industry 4.0 Factory Actually Looks Like

The Power of the Digital Twin, Quantified.

Move beyond static models.

Our digital twin solutions create dynamic, living replicas of your operations, enabling risk-free experimentation and proactive problem-solving in real-time. Paired with robust industrial IoT and data acquisition systems, this gives you unprecedented visibility.

See how virtual insights lead to tangible improvements in efficiency, cost reduction, and quality control on your plant floor.

Advanced Manufacturing for Agility & Excellence

Build resilient, responsive operations with advanced technologies. Flexible manufacturing and additive manufacturing (3D printing) revolutionize production, enabling on-demand capabilities and accelerating innovation.

Our expertise in MES and 3D laser scanning streamlines workflows, reduces errors, and ensures precise planning.

We don't just throw technology at problems; we strategically implement solutions for sustained operational excellence and competitive edge.

From Cost-Center to Profit-Driver

The Shift to Outcome-Based Manufacturing

In a volatile market, focusing on outcomes is no longer optional—it's essential for survival. This whitepaper is for manufacturing & engineering leaders who know their current systems are holding them back.

You'll learn how to implement an outcome-based model, leverage advanced technologies, and transform your operations from rigid and reactive to agile and proactive.