Mitigate Risk and Optimize Performance in Complex Industrial Systems

The greatest threat to profit is unseen risk.

Traditional consulting stops at reports; Design Systems delivers implemented solutions.

We combine advanced failure analysis with proprietary comprehensive manufacturing risk assessment to secure your operations.

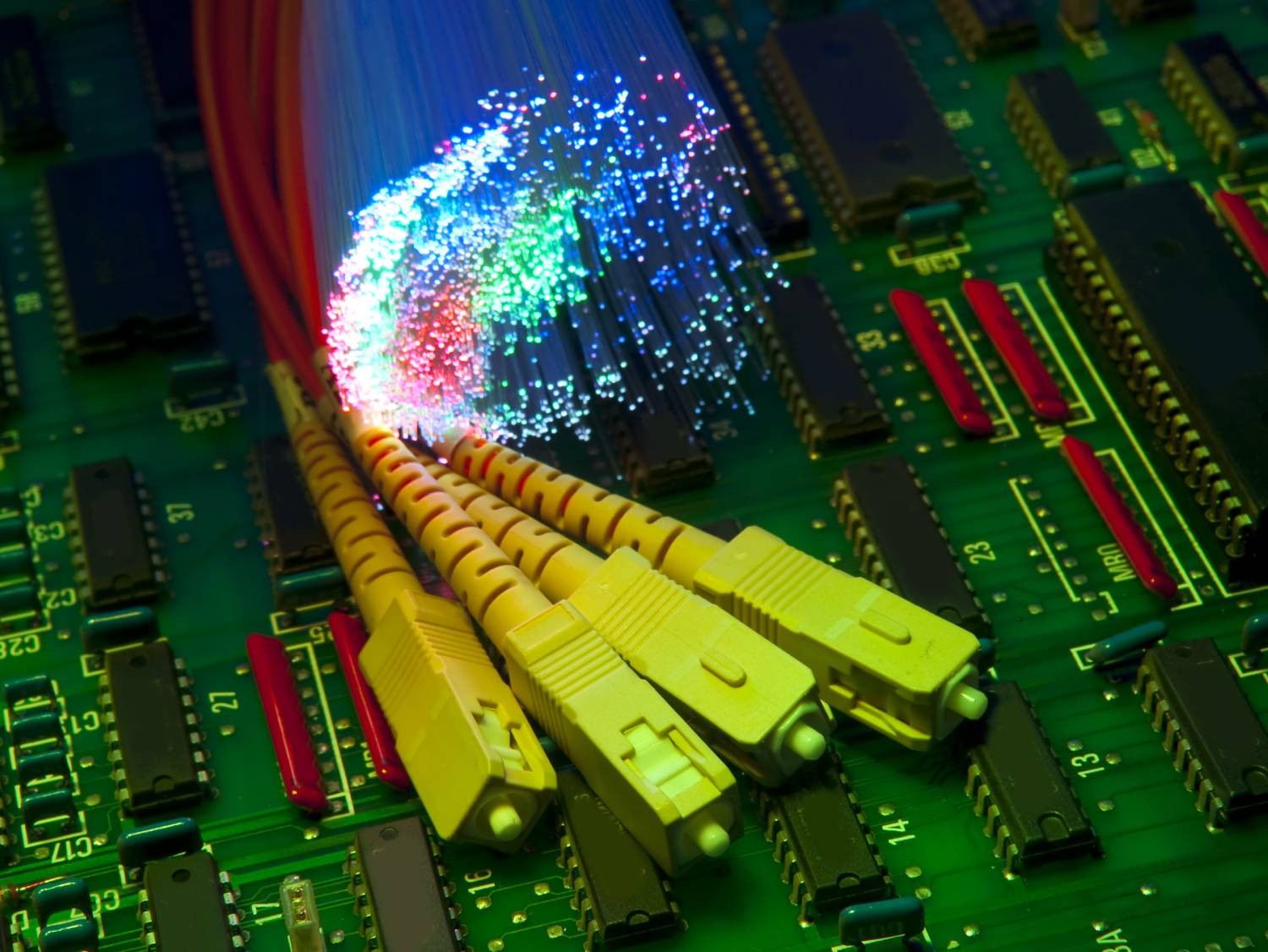

Our industrial engineering experts diagnose system vulnerabilities, weak links in supply chain resilience, and leverage Industrial IoT data and deep-dive diagnostics to ensure operational readiness.

Proactive Risk Management for Manufacturing

Today's manufacturing & engineering leaders face unrelenting pressures: economic instability, supply chain chaos, and geopolitical shifts.

We go beyond obvious threats, identifying the full spectrum of operational, safety, financial, and reputational risks.

Our deep failure analysis capability transforms your approach from reactive to proactive, building true supply chain resilience and safeguarding your future.

Achieve Operational Readiness with Smart Solutions

Identifying risks isn't enough; you need to operate through them.

We offer a methodical approach to mitigation, leveraging industrial engineering expertise for root cause analysis, strategic planning, and process optimization.

Powered by Industrial IoT, real-time monitoring, predictive maintenance, and anomaly detection ensure your operational readiness and prevent costly incidents before they occur.

Transforming Failure Analysis into Operational Reliability

We deliver outcome-focused solutions by aligning every stage of our consulting process with your required quantifiable results. For critical industrial systems, our approach to failure analysis is the cornerstone of this value-driven philosophy.

We don't just find a broken part; we diagnose a broken process with the singular goal of implementation.

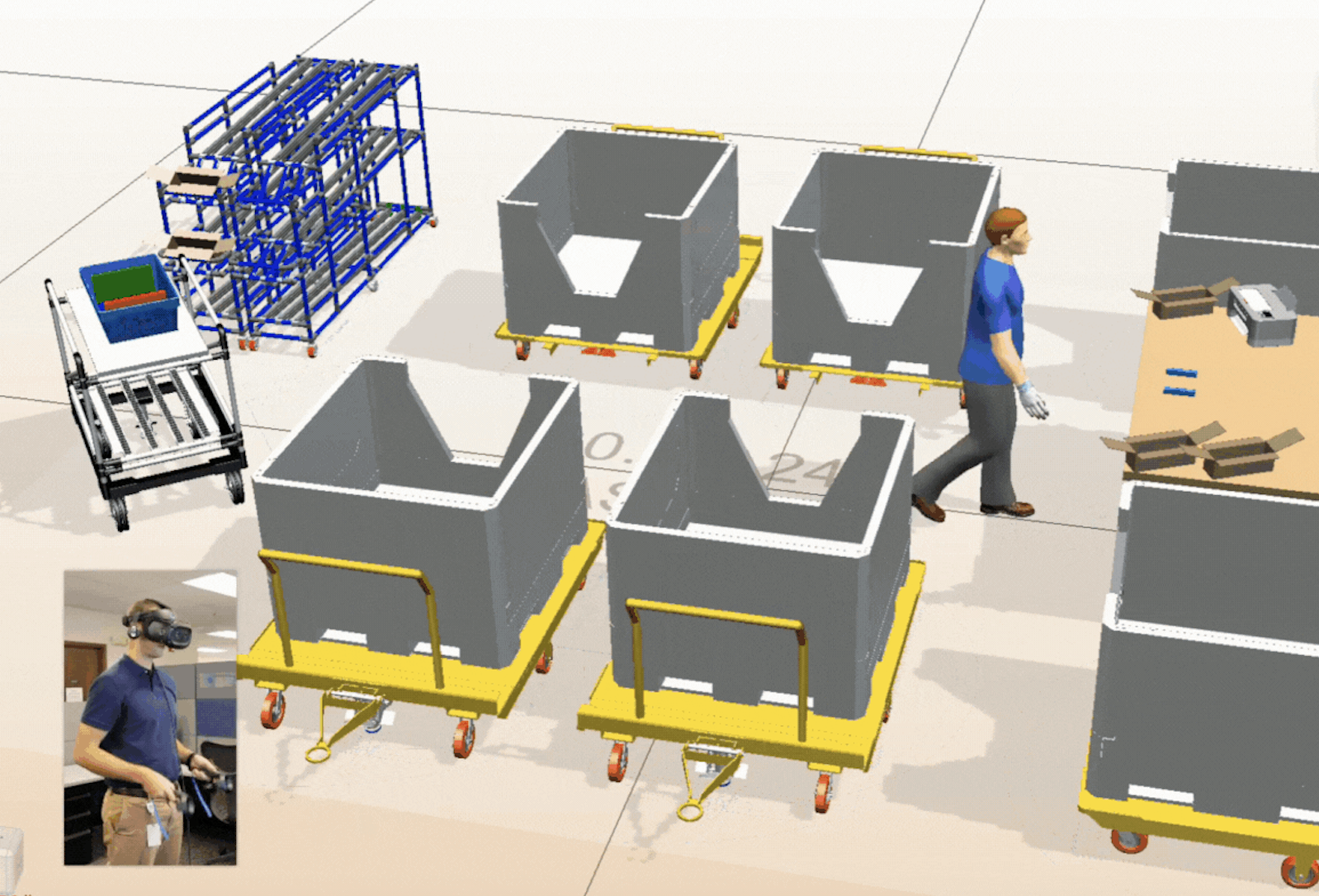

Advanced Diagnostic & Simulation

We deploy laser scanning and 3D model development alongside advanced diagnostic tools to reconstruct the failure event, identifying not just the component failure, but the cascading effects of process, material, and operator error.

Learn how a robust failure analysis process can uncover hidden weaknesses across an entire system in our blog: The Strategic Advantage of Failure Analysis

Measurable Results in Asset Performance Management

The long-term impact of our implemented solutions is a demonstrable reduction in unscheduled downtime, a higher overall asset utilization (OAU), and a significant uplift in overall asset performance management maturity.

For industry leaders, this means mitigated risk, a superior return on your engineering investments, and a definitive end to the value to money paradox that plagues traditional consulting.

Our failure analysis is the starting point for delivering operational peace of mind.

From Cost-Center to Profit-Driver

The Shift to Outcome-Based Manufacturing

In a volatile market, focusing on outcomes is no longer optional—it's essential for survival. This whitepaper is for manufacturing & engineering leaders who know their current systems are holding them back.

You'll learn how to implement an outcome-based model, leverage advanced technologies, and transform your operations from rigid and reactive to agile and proactive.